Key Dates

Image Credit :

Project Overview

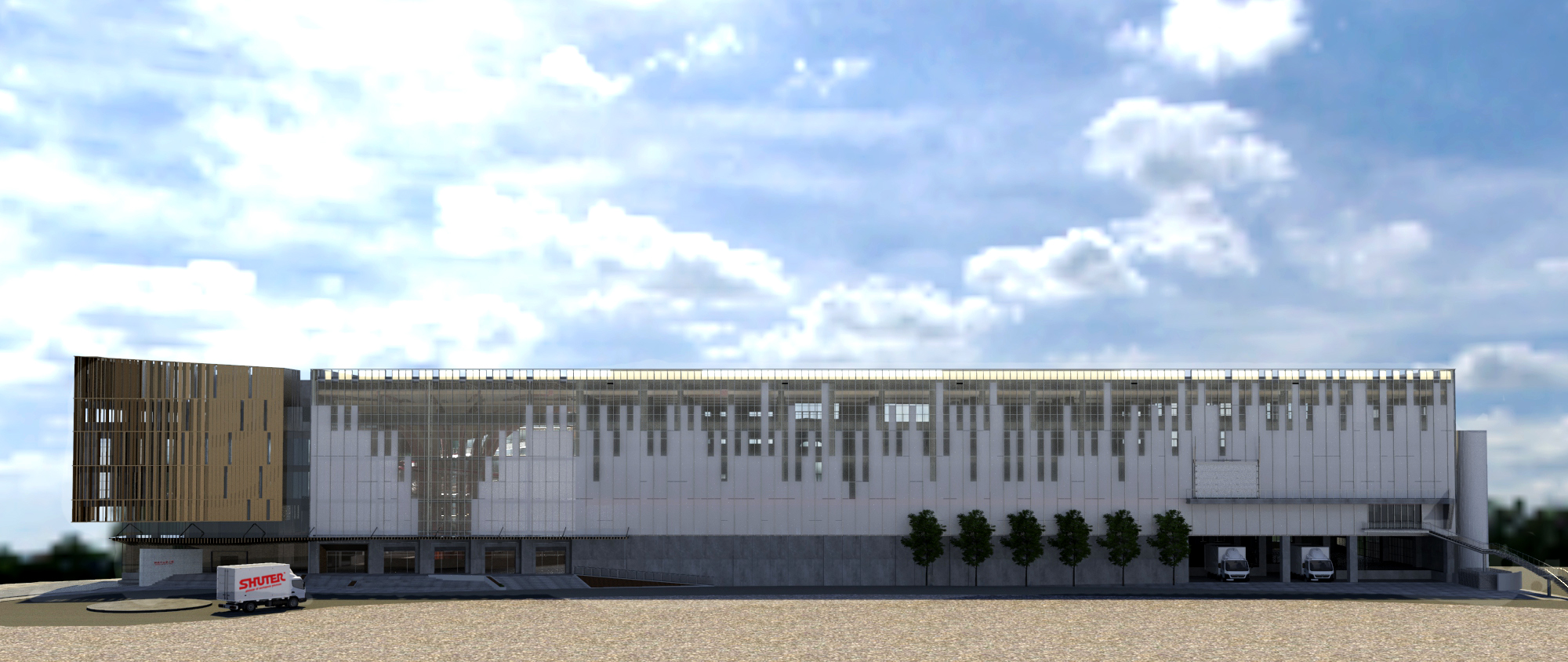

The Shuter Babbuza Dreamfactory is a groundbreaking architectural project that embodies the efforts of Taiwanese storage solution manufacturer Shuter Enterprise to solve the ecological imbalances in manufacturing. The central feature of the architectural design is a 30.8-meter-tall wooden structure, aptly named the Tree of Life. The walls are made of translucent, breathable polycarbonate. Other sustainable elements include a 4,030 sqm solar photovoltaic energy system and a 228,650 liters rainwater harvesting system. It is also a tourism factory, featuring a world-first Austronesian museum.

Organisation

Team

Williamson Architects Pty Ltd, T.E&C Architects & Associates

Project Brief

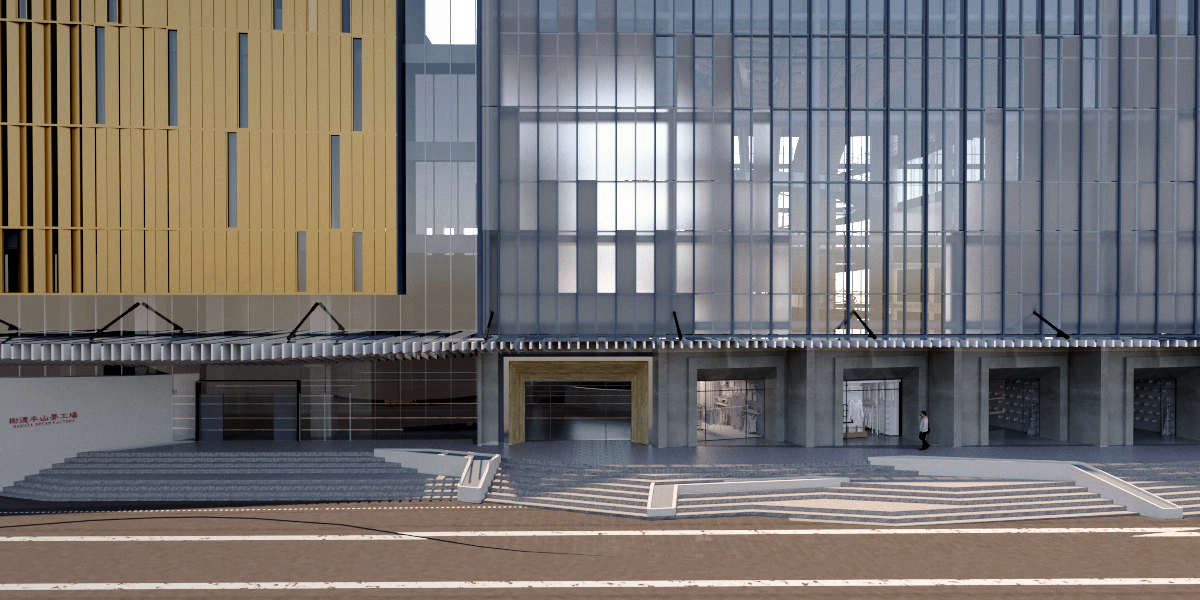

The Shuter Babbuza Dreamfactory embodies a building concept unique to the manufacturing sector. This groundbreaking architectural project represents Shuter’s efforts to solve the ecological imbalances created due to current manufacturing systems. Taking inspiration from the banyan tree, which has been regarded in Taiwan as an important symbol of shelter and strength for centuries, the design combines structural necessity with the latest in eco-friendly architecture. A 30.8-meter-tall wooden structure (aptly named the Tree of Life) stands stately and supportive in the center of the building. The spruce used in the Tree of Life, for example, is free from stains or paint–allowing it to breathe. The walls of the deceptively box-like manufacturing complex are made of translucent polycarbonate, which allows air and sunlight to flow naturally throughout the manufacturing space. The roof of Babbuza Dreamfactory is lined with a 4,030 sqm solar photovoltaic energy system that can generate up to 1000 kW of power. The rainwater harvesting system recycles 228,650 liters of water. The factory features a world-first crane-less ASRS (Automatic Storage Retrieval System)–the highest in the world at 46-meters-tall–that uses state-of-the-art robotics to stack and store heavy products. An automated painting facility uses the latest in robotic technology to protect the health of employees. At over 15,000 square meters, Babbuza Dreamfactory is also set to become the most significant tourist factory in Taiwan. Shuter is partnering with MIT (Made in Taiwan) brands, designers, craftspeople, restaurateurs, government agencies, and indigenous communities to create retail and education spaces.

Project Innovation/Need

Babbuza Dreamfactory has its roots in the 2014 Dreamworks Green Factory architecture competition, which was funded by fifty-year-old Taiwanese storage solutions manufacturer Shuter Enterprise. Shuter was seeking concepts that balanced the needs of plastics and steel manufacturing with green-focused building solutions. They wanted to inject an aspect of the humanities into the Taiwanese manufacturing sector. The winning proposal by Australian firm Williamson Architects conceived “the factory as a tremendous tree,” the competition jury noted. “They made the tree the main structure of the factory, which directly connects the design concept to the environment.” Brad Williamson, the studio’s founder, notes that the Williamson Architect team enjoys the freedom and speed of architectural competitions. “The Babbuza Dreamfactory was a particularly good competition brief,” he says. “It offered an irresistible paradox–green vs. industrial–and huge potential for experimentation.” As construction and engineering teams realised the concept, they stayed true to this renegade nature. The banyan tree that was so central to the firm’s vision of sustainability now stands proud in Babbuza’s eight-floor foyer. This “Tree of Life” is itself a feat of engineering creativity: made entirely of spruce, it stands 30.8 meters high and is entwined with a vine-like skywalk over 350 meters long. Creativity extends to the functions of Babbuza Dreamfactory, too. The factory will soon open its doors to the public, who can visit Taiwan’s first and only Austronesian Culture Hall, restaurants serving local fare, shops managed by Taiwanese craftspeople and MIT (Made in Taiwan) brands, and a youth entrepreneur hub.

Design Challenge

Babbuza Dreamfactory represents Shuter Enterprise’s efforts to solve the ecological imbalances created due to current manufacturing practices. Traditionally, Taiwanese factories are dark, noisy, airless buildings constructed quickly of cheap materials. The first challenge came when Yira Wu, second-generation owner and current Chairman of Shuter Enterprise, wanted to create a healthier, safer, and more productive manufacturing complex. In 2014, Wu launched the Shuter Dreamworks Green Factory architecture competition. Concepts came rolling in, but even the selection of the winner proved difficult, with jury head Sou Fujimoto deciding none of the submitted projects met the first-prize sustainability criteria. Instead, the contract went to the third prize winner, Australian studio Williamson Architects, who beat out multinational firms like Mecanoo and NAAD. Construction broke ground in late 2017 on the steep mountainside site in Nantou County, with engineering contractors leaning on skills uniquely developed in Taiwan, where flat land is scarce. Williamson Architect’s concept hinged on a central wooden tree-like structure situated in the foyer of the complex. The 30.8-meter-high wooden Tree of Life, the tallest structure of its kind in the region, was shipped to Taiwan in sections and had to be assembled like a jigsaw. The design and installation were completed in Taiwan, but the fabrication was outsourced to experts in Germany. Another challenge was recreating the original breathable exterior wall design conceptualized by Williamson Architects. After much experimentation and budget rejigging, the construction team eventually settled on a translucent polycarbonate membrane, letting air and light filter throughout the entire building.

Sustainability

Organic elements like water, air, and sunlight have been integrated into the core of the Babbuza Dreamfactory architectural design to counter this perception. The spruce used to craft the Tree of Life, for example, is free from stains or paint–allowing it to breathe–and it sits in a building that embraces carbon neutrality. Traditionally, factory buildings are enclosed, the interiors dark, noisy, and airless. But the walls of this box-like manufacturing complex are made of translucent polycarbonate, which allows air and sunlight to flow naturally. Conceptually, this unique coating represents both the upper layers of a forest canopy while simultaneously symbolizing the various types of see-through plastic products made by Shuter Enterprise. Automation is integrated into the architecture of Babbuza Dreamfactory as much as it is the functional design, relieving workers of the burden of heavy lifting and other dangerous activities. The roof of Babbuza Dreamfactory is lined with a 4,030 sqm solar photovoltaic energy system that can generate up to 1000 kW of power, and the rainwater harvesting system recycles as much as 228,650 liters of water. A world-first crane-less ASRS (Automatic Storage Retrieval System)–the highest in the world at 46-meters-tall–uses state-of-the-art robotics to stack and store products. An automated painting facility with robotic technology significantly shortens production times and protects the health of employees. The 1,322 square meter Babbuza Dreamfactory offices overlook the tropical rainforest, which has been preserved during the creation of the Nantou eco-industrial park–the openness and greenness creating a healthier work environment.

Architecture - International

This award celebrates the design process and product of planning, designing and constructing form, space and ambience that reflect functional, technical, social, and aesthetic considerations. Consideration given for material selection, technology, light and shadow.

More Details